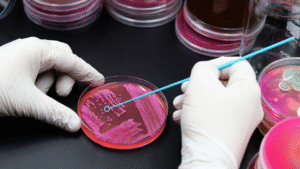

Disinfectant efficacy testing is one of the most critical components in the pharmaceutical industry, particularly the surface challenge studies. These studies ensure that disinfectants used in cleanrooms and controlled environments can eliminate microorganisms from the surfaces within the facility.

However, one common mistake companies make is overlooking the importance of surface selection during disinfectant validation studies. The effectiveness of a disinfectant is not universal. It varies depending on the type of material, surface texture, and environmental conditions. That means the effectiveness of disinfectant on one surface may not be the same on another surface.

In this blog, we will explore:

- Why surface selection is critical in disinfectant efficacy testing

- Common surfaces used in pharmaceutical facilities

- Regulatory expectations and compliance requirements

Why Surface Selection Matters in Disinfectant Efficacy Testing

Pharmaceutical facilities contain a wide range of surfaces with unique physical and chemical properties. These properties significantly influence microbial adhesion, survival, and resistance to disinfectants.

Before performing a surface challenge test, companies must conduct a detailed assessment of materials used in cleanrooms, production areas, laboratories, and equipment surfaces.

Key Factors That Influence Disinfectant Performance

- Surface Porosity

- Non-porous surfaces (e.g., stainless steel, glass) allow better disinfectant contact.

- Porous materials may absorb disinfectants, reducing effective contact time.

- Surface Texture

- Smooth surfaces are easier to disinfect.

- Rough or irregular surfaces can shield microorganisms.

- Chemical Compatibility

- Some disinfectants may react with certain plastics or coatings.

- Surface degradation can impact long-term contamination control.

- Microbial Adhesion

- Some materials promote biofilm formation.

- Biofilms dramatically reduce disinfectant efficacy.

The goal is to replicate real-world conditions during validation. The test carriers selected should represent the worst-case surfaces in the facility.

Common Surfaces Used in Pharmaceutical Facilities

Below are the most commonly validated surfaces in pharmaceutical disinfectant efficacy studies:

1. Stainless Steel

Stainless steel is one of the most widely used materials in pharmaceutical manufacturing.

Applications:

- Equipment surfaces

- Cleanroom furniture

- Autoclave chambers

- Isolator interiors

In cleanrooms and equipment manufacturing, austenitic stainless steels such as SS 304 and SS 316/316L are the most commonly used due to their excellent corrosion resistance, durability, and cleanability.

In pharmaceuticals, SS 316L is preferred because it contains molybdenum, which enhances resistance to chemical corrosion. It also has low carbon content and reduces the risk of corrosion at weld joints.

Stainless steel is often considered the baseline surface in disinfectant validation studies.

2. Glass

Glass is frequently used in laboratory settings and observation panels.

Applications:

- Laboratory glassware

- View panels

- Equipment windows

Glass provides a controlled surface for evaluating disinfectant performance under standardized conditions.

3. Plastic Materials

Plastic surfaces are extremely common but often underestimated in validation programs.

Common Types:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Polycarbonate

Plastic materials may present greater challenges than stainless steel and must not be ignored during validation.

4. Epoxy-Coated Surfaces

Epoxy flooring and countertops are common in cleanrooms.

Characteristics:

- Typically smooth

- Chemically resistant

- Durable

However, some epoxy formulations include surface textures or additives that can affect disinfectant contact and microbial removal.

Additional Surfaces to Consider (Often Missed)

Many facilities only validate on stainless steel, but regulatory expectations are evolving.

Consider including:

- Vinyl flooring

- Painted walls

- Gaskets and seals

- Silicone tubing

- Polyurethane surfaces

- Rubber components

These areas may act as hidden contamination reservoirs if not properly validated.

Regulatory Expectations for Disinfectant Efficacy Testing

Regulatory agencies such as:

- European Committee for Standardization (CEN)

- US FDA

- EMA

- WHO

- ISO standards (ISO 14644)

Expect disinfectant validation studies to reflect actual facility conditions.

What Regulators Expect:

- Surface Relevance: Test surfaces must represent materials used in classified areas.

- Worst-Case Evaluation: Include challenging surfaces such as textured or slightly porous materials.

- Microbial Selection: Use environmental isolates in addition to standard ATCC strains.

- Contact Time Validation: Demonstrate efficacy within practical in-use contact times.

- Neutralization Studies: Validate neutralizers to ensure accurate recovery of surviving organisms.

- Log Reduction Criteria: Usually, ≥3 log reduction for bacteria and ≥2 log reduction for fungi.

- Documentation: Must include detailed protocols, raw data, deviation reports, and justification for surface selection.

Risk-Based Approach to Surface Selection

Instead of randomly choosing surfaces, adopt a risk-based contamination control strategy:

- Identify high-touch surfaces

- Identify hard-to-clean areas

- Consider Frequency of Human Contact

- Review environmental monitoring trends

- Include surfaces with recurring contamination

- Align with Contamination Control Strategy (CCS)

This aligns with modern regulatory focus on Contamination Control Strategy (CCS) under EU GMP Annex 1.

A risk-based approach ensures that disinfectants are validated on the surfaces that really matter within your facility.

In today’s regulatory environment, surface selection must be defensible, documented, and data-driven, not convenient.