Non viable particle monitoring during aseptic operations is very critical and provides an instant status of the aseptic environment, while viable monitoring does not provide immediate results. The cleanliness of the air and the efficiency of filters can be assessed through non-viable particle monitoring. The Grade A zone should be continuously monitored during aseptic manufacturing and provide an alarm when alert limits are exceeded.

The EU GMP (Annex 1) specifies limits for both particles with diameters≥0.5 µm and ≥5.0 µm, particularly in aseptic manufacturing. According to the guidelines, particle monitoring should be undertaken throughout the critical manufacturing process for Grade A. The Grade A area should be continuously monitored for particles to capture all interventions and events.

The system should frequently correlate each sample result with alert and action levels and trigger an alarm when alert levels are exceeded. Procedures should define the actions to be taken in response to alarms, including the consideration of additional microbial monitoring.

As aseptic processing environments improve, non-viable monitoring systems have also evolved and are integrated into the aseptic processes. The permanently installed, online, automated particle counters will reduce the need for operator presence in grade A and B areas to place probes and take samples. It also reduces the need for human intervention in data management.

Sampling Locations in Non-Viable Particle Monitoring

The selection of sampling locations for a non-viable particle monitoring program is crucial. These locations should be identified through risk assessment. During the risk assessment, the cleanroom classification, the type of process being performed, and the likelihood of contamination must be taken into account. The goal is to monitor areas where there is a greater risk of product exposure or contamination.

One of the primary areas for sampling is in critical zones where the product or sterile surfaces are exposed to the environment. For example, in pharmaceutical cleanrooms, this would include areas such as filling lines, stopper bowls, vial capping stations, and places where aseptic connections are made. These are classified as Grade A (or ISO Class 5) and require continuous or frequent monitoring during operations to ensure that the environment remains within acceptable limits.

Background or support areas are also important sampling locations. These areas surrounding the critical zones are usually classified as Grade B, which act as a buffer to protect the product from contamination. Airlocks, gowning rooms, material transfer hatches, and preparation rooms fall into this category. These areas may not require continuous monitoring, but should be checked regularly, especially during production.

Additionally, sampling can be performed at air supply outlets and return air grilles. It will help verify the integrity and performance of the HVAC system.

Finally, cleanroom designers and quality teams may identify additional sampling points based on the building layout, operations, and historical environmental monitoring data.

All sampling locations should be mapped on the layout, documented, and justified as part of the cleanroom’s environmental monitoring plan.

The following are the maximum permitted particle sizes in different grades, as per regulatory guidelines.

| Grade | At rest | In operation | ||

| The maximum permitted number of particles/m3 equal to or greater than the tabulated size | ||||

| 0.5 µm | 5 µm | 0.5 µm | 5 µm | |

| A | 3520 | 20 | 3520 | 20 |

| B | 3520 | 29 | 352,000` | 2900 |

| C | 352,000` | 2900 | 3,520,000 | 29,000 |

| D | 3,520,000 | 29,000 | Not defined | Not defined |

For grade D, in-operation limits are not defined. The manufacturer can establish in-operation limits based on a risk assessment and routine data trend, where applicable.

Challenges in Sampling | Isokinetic Sampling

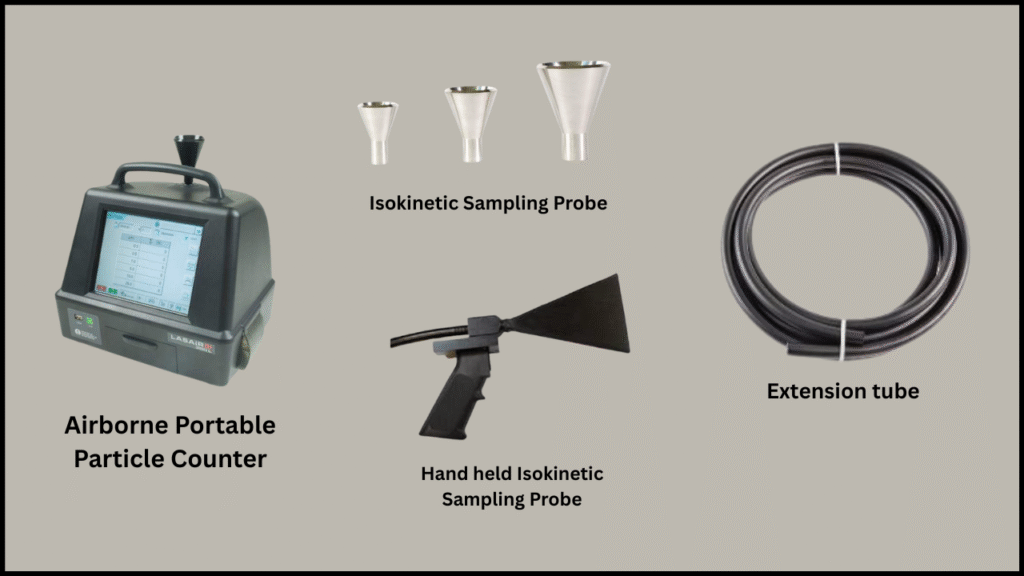

Sampling of non-viable particles is always a challenge. Laser-based particle counters are commonly used to measure non-viable particles. These instruments draw air samples and detect/count particles based on light scattering.

Sampling of particles consists of entraining the particles and transporting them to a sensor for detection. Both entraining and transporting are dependent on the size of the particles. Representative sampling is achieved only when the probe is aligned with the airflow, and the velocity of air entering the probe is equal to the velocity of air in the room. This is called isokinetic sampling.

Isokinetic sampling enables the capture of heavier particles in turbulent airflow environments. The accurate particulate concentration will therefore be measured. If the probe is not aligned correctly, small particles can be dragged, but large particles may escape the probe, which may lead to a false reading of particles present in the room.

During monitoring, the sample probes should be positioned at working height to maximize the probability of detecting particles. In unidirectional airflow environments, probes should be positioned so that they point into the airflow. In non-unidirectional airflow, where the direction of the airflow being sampled is not controlled, the inlet of the sampling probe shall be directed vertically upward.

The particle counting devices use a funnel-shaped collector to concentrate the air sample so that a larger volume of air is measured. Most portable particle counters have direct-mount isokinetic sampling probes. An extension tube can be used to reach locations that do not have access to particle counting devices. However, it is recommended that the length of the tubing not exceed 6 feet, as large particles remain in the tube itself.

Read Viable Monitoring in Cleanrooms.